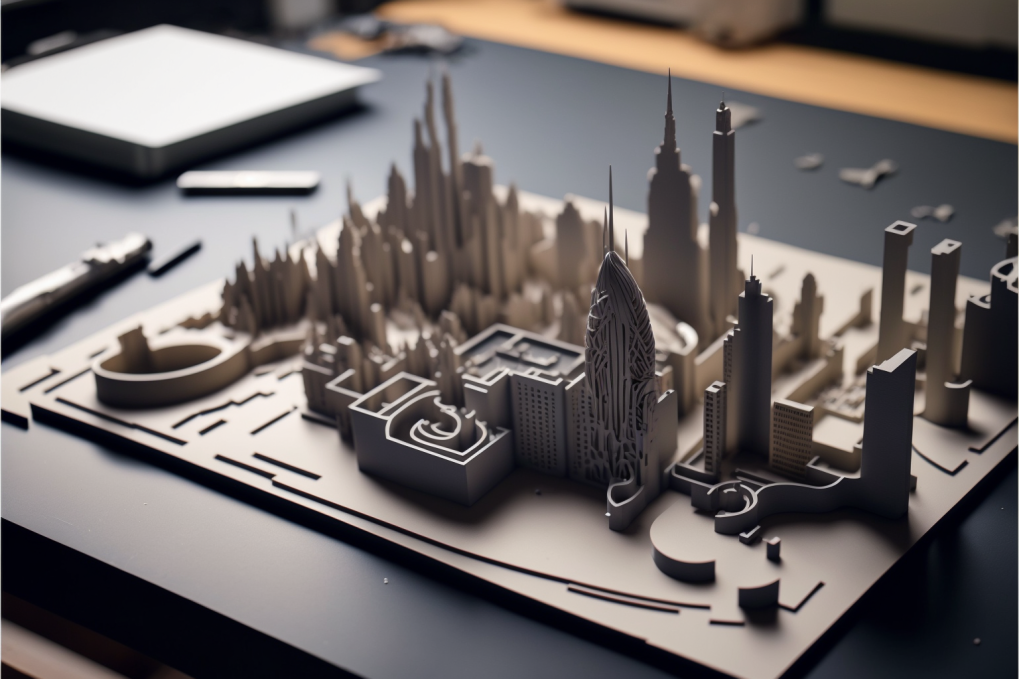

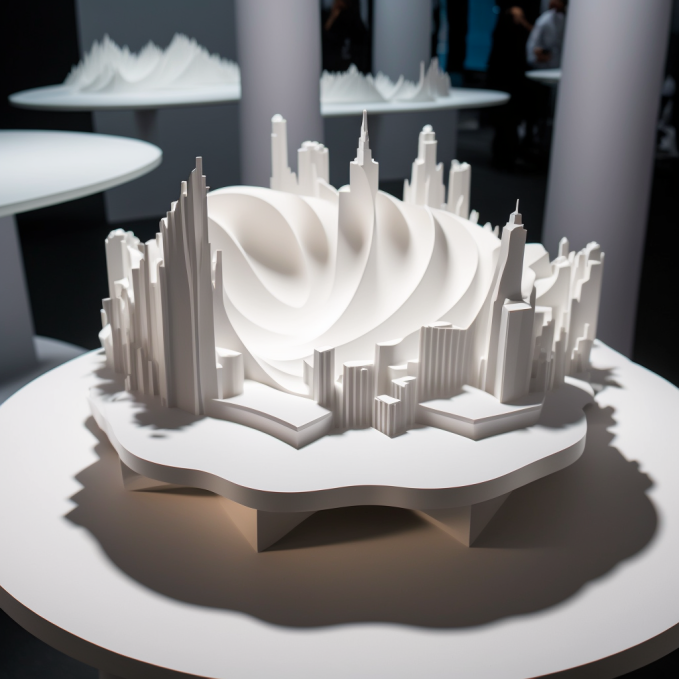

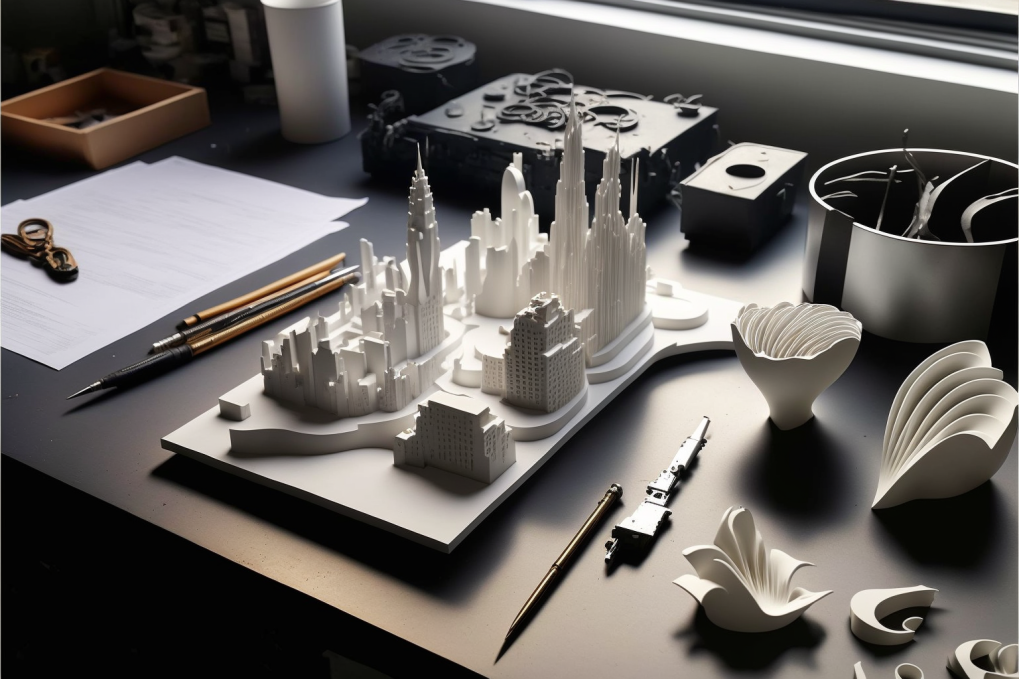

3D print

Professional 3D printing services for architectural offices: presentation, working and competition models

Models, which had to be laboriously and time-consumingly produced by hand from cardboard, foam or even wood, are an essential part of every architectural project. However, they are also a major cost factor in this, which, moreover, often has to be provided before the contract for the realisation has even been awarded. This is where 3D printing provides a remedy: the additive manufacturing process, in which a model is created layer by layer, can result in time and cost savings of up to 70% compared to conventional methods. Especially with complex models, the performance gap between the methods is striking. However, an in-house 3D printing department is not worthwhile for every architectural office. We therefore offer this service for you.

Let us 3D print your models for you. We produce exactly according to your standards and ideas.

- Presentation models

- Working models

- Competition models

- Town planning models

- Landscape models

Especially for complex designs and building projects, there are no limits to the 3D printing process. Even very filigree and delicate designs can be produced with this technology. The surface quality of the results is in no way inferior to that of a conventional model, as we work with layer thicknesses in the µm range. Your advantage with us: in combination with our other offers, the required 3D modelling time can be reduced, thus saving costs. Please contact us and we will advise you individually on your wishes and ideas.

SLA printing process

We print in the SLA process and not (like many other suppliers) in the FDM process, whereby a much higher degree of precision can be achieved. Stereolithography (SLA) is the 3D printing process with the longest history, or the longest-used method of additively manufacturing components using a 3D printer.

As early as 1983, the physicist Chuck Hull developed the process and just one year later he developed the first stereolithography printer as well as the STL interface (STereoLithography, Standard Tessellation Language) for 3D printers, which is still common today. In the SLA process, which is part of rapid prototyping, the workpiece is steadily lowered into a bath of liquid photopolymer and irradiated with UV radiation by a laser. Photopolymers are curable (reactive) resins such as synthetic and epoxy resins. A wiper or dispenser distributes the liquid plastic evenly over the work surface, then one or more lasers are used, which bundle UV radiation very intensively and can thus irradiate the reaction resins in a defined way. In this way, even fine structures can be cured. Once a layer has cured, the component is lowered by a layer thickness (0.2-0.5 millimetres) into the polymer bath, new resin is distributed and the laser repeats the selective curing of the next layer. In this way, an object is also built up layer by layer in this process. The materials used in the SLA process are light-curing synthetic resins. These so-called photopolymers are available on an acrylic, epoxy or vinyl basis. At room temperature, the materials are initially liquid and can then be polymerised by laser. In order to achieve certain material properties, the synthetic resins are mostly enriched with additives, special molecules and monomers. Depending on the material specification used, the components produced can thus be either impact-resistant and high-strength, or flexible and pliable.